Umbala wepuletiI-PPGI / PPLL iyinhlanganisela yensimbi nopende, ngakho-ke ubukhulu bawo bususelwa ekukhulumeni kwepuleti lensimbi noma ngobukhulu bomkhiqizo ophelile?

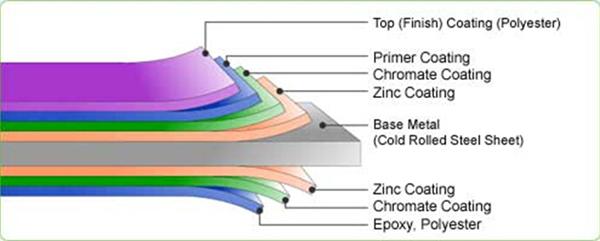

Okokuqala, ake siqonde ukwakheka kwepuleti lemibala elihlanganisiwe lokwakha:

(Umthombo Wezithombe: I-Intanethi)

Kunezindlela ezimbili zokuveza ubukhulu beI-PPGI/I-PPLL

Okokuqala, ubukhulu bokuqedwa kwepuleti elihlanganisiwe lemibala

Isibonelo: Ubukhulu obuqedile be-0.5mmumbala weshidi ohlanganisiwe, ukupenda ukuqina kwefilimu kwama-microns angama-25/10

Ngemuva kwalokho singacabanga ngombala ohlanganisiwe wombala (ishidi elibandayo elibandayo + ubukhulu obugqikele ungqimba, ubukhulu bokuguqulwa kwamakhemikhali bunganakwa) ubukhulu bungu-0.465mm.

I-Common 0.4mm, 0.5mm, 0.6mm Umbala weshidi ohlanganisiwe, okungukuthi, ubukhulu bomkhiqizo ophelile, olula kakhulu ngathi ukukala ngqo.

Okwesibili, amakhasimende acacisiwe izidingo zombala ohlanganisiwe wokubumbana

Isibonelo: Ubukhulu be-substrate bombala we-0.5mm umbala ohlanganisiwe, ukupenda kwamafilimu ama-microns angama-25/10

Lapho-ke ubukhulu bomkhiqizo osuqediwe ngu-0.535mm, uma udinga ukumboza ifilimu le-PVC ukuvikela indawo yebhodi, kudingeka singeze ubukhulu befilimu, kusuka kuma-80 ama-microns.

Ubukhulu bomkhiqizo obuqediwe = umbala ohlanganisiwe we-substrate (ishidi elibandayo eligoqiwe

Umehluko ongenhla we-0.035mm, siyakubona lokho empeleni kuyigebe elincane kakhulu, kepha ukusetshenziswa kwesidingo samakhasimende kufanele futhi kuqaphele kakhulu. Ngakho-ke, lapho u-oda, sicela wazise isidingo ngokuningiliziwe.

Ungawukhetha kanjani umbala wekhoyili ehlanganisiwe

Umbala ohlanganisiwe wokukhetha umbala wepuleti: Ukukhetha kombala ikakhulukazi ukucubungula umdlalo nemvelo ezungezile kanye nokuzilibazisa komsebenzisi, kepha kusukela endaweni yokuzilibazisa yomsebenzisi, kepha kusukela ekubukweni kokusetshenziswa kobuchwepheshe, ukumboza okukhanyayo okukhanyayo ukukhetha umngcele omkhulu we Ukuzikhethela, ungakhetha ukuqina okuphezulu kwemibala engaphansi (njenge-titanium dioxide, njll.), kanye nokuvezwa kwe-Thermal okushisayo (ukuboniswa kwe-coeffings yezimbali ezimnyama kuze kube yilapho uphindwe kabili ehlobo Ukuhlanganisa ngokwako kuphansi, okuwukunwebeka impilo ye-coating lokhu kunenzuzo ekunwetshisweni kwempilo ye-coating.

Isikhathi sePosi: Dec-15-2024