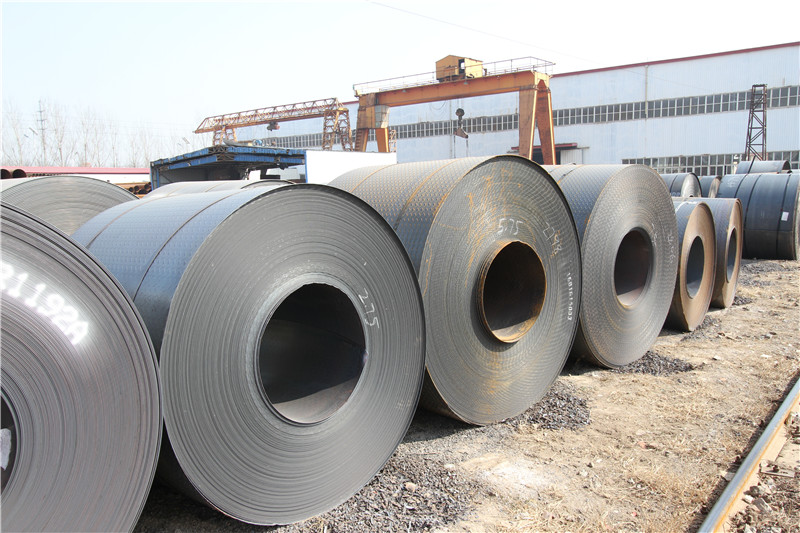

1 Letlapa le Tletseng le Chesang/Leqephe le Koloeng le Chesang/Koele ea tšepe e kolobisitsoeng e chesang

Khoele e kolobisitsoeng e chesang hangata e kenyelletsa khoele ea tšepe e botenya bo bohareng, khoele e tšesaane e tšesaane e pharaletseng le poleiti e tšesaane e chesitsoeng. Lesela la tšepe le bophara bo bohareng ke e 'ngoe ea mefuta e emelang ka ho fetesisa,' me tlhahiso ea eona e bile karolo ea bobeli ho tse tharo ea kakaretso ea coil e kolobisitsoeng e chesang. Mahareng-tenya ka bophara tšepe hlobolisa e bua ka botenya ≥3mm le <20mm, bophara ≥600mm; chesang phuthoa tšesaane ka bophara tšepe hlobolisa e bua ka botenya <3mm, bophara ≥600mm; Letlapa le le leng la tšepe le nang le botenya <3mm.

Lisebelisoa tse ka Sehloohong:Koele e kentsoeng e chesanglihlahisoa na le matla a phahameng, toughness e ntle, ho sebetsa bonolo le ho bōpa le weldability e ntle le thepa e 'ngoe e babatsehang, ho pharaletseng sebelisoa ka substrates batang phuthoa, likepe, likoloi, marokho, kaho, mechine, liphaephe tsa oli, likepe khatello le liindasteri tse ling tsa tlhahiso.

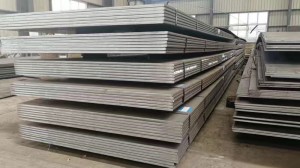

2 Leqephe le Kolohileng le Batang/Cold Rolling Coil

Cold phuthoa lakane le khoele ke chesang phuthoa khoele e le thepa e tala, phuthoa ka mocheso kamoreng tlas'a mocheso recrystallization, ho akarelletsa le poleiti le khoele. E 'ngoe ea ho fana ka lakane e bitsoa tšepe ea tšepe, e tsejoang hape e le lebokose kapa poleiti e bataletseng, bolelele bo bolelele haholo, phepelo ea li-coil e bitsoa tšepe ea tšepe e tsejoang hape e le coil. Botenya ke 0.2-4mm, bophara ke 600-2000mm, bolelele ke 1200-6000mm.

Lisebelisoa tse ka Sehloohong:Cold rolled steel stripe na le mefuta e mengata ea tšebeliso, joalo ka tlhahiso ea likoloi, lihlahisoa tsa motlakase, li-rolling stock, lifofane, lisebelisoa tse nepahetseng, ho kenya lijo joalo-joalo. Cold plate e entsoe ka tšepe e tloaelehileng ea tšepe e chesang e kolobisitsoeng ka tšepe, ka mor'a hore ho be le serame se eketsehileng se entsoeng ka botenya ba tšepe bo ka tlase ho 4mm. Joalo ka mocheso oa kamore, ha e hlahise oxide ea tšepe, boleng ba holim'a poleiti e batang, ho nepahala ha maemo a holimo, ho kopantsoe le annealing, thepa ea eona ea mochini le thepa ea ts'ebetso e ntle ho feta lakane e kentsoeng ka mocheso, libakeng tse ngata, haholo-holo lefapheng la tlhahiso ea lisebelisoa tsa lapeng, butle-butle e sebelisitsoe ho nkela lakane e chesang.

3 poleiti e teteaneng

Letlapa le mahareng le bolela botenya ba poleiti ea tšepe ea 3-25mm, botenya ba 25-100mm bo bitsoa poleiti e teteaneng, botenya bo fetang 100mm bakeng sa poleiti e teteaneng e eketsehileng.

Lisebelisoa tse ka Sehloohong:Letlapa le botenya bo mahareng le sebelisoa haholo boenjiniere ba kaho, tlhahiso ea mechini, tlhahiso ea lijana, kaho ea likepe, kaho ea borokho joalo-joalo. E sebelisetsoa ho etsa lijana tse fapaneng (haholo-holo likepe tsa khatello), likhetla tsa boiler le meaho ea borokho, hammoho le sebopeho sa mapolanka a koloi, likhetla tsa likepe tsa lipalangoang tsa noka le leoatle, likarolo tse ling tsa mochini, le tsona li ka bokelloa le ho ts'oaroa ka likarolo tse kholo.

Strip steel ka kutloisiso e pharaletseng e bolela coil kaofela e le boemo ba ho pepa, bolelele ba tšepe e batlang e le telele e bataletseng. Narrowly e bua ka bophara moqotetsane ea khoele, ke hore, hangata bitsoa e moqotetsane hlobolisa tšepe le mahareng le bophara hlobolisa tšepe, ka linako tse ling haholo-holo moqotetsane hlobolisa tšepe. Ho ea ka index ea naha ea lipalo-palo, khoele e ka tlase ho 600mm (ntle le 600mm) ke tšepe e moqotetsane kapa tšepe e moqotetsane. 600 mm ho ea holimo ke sephara se sephara.

Lisebelisoa tse ka Sehloohong:Strip tšepe e sebelisoa haholo indastering ea likoloi, indasteri ea tlhahiso ea mochini, kaho, sebopeho sa tšepe, lisebelisoa tsa ts'ebeliso ea letsatsi le letsatsi le likarolo tse ling, joalo ka tlhahiso ea phala ea tšepe e cheselitsoeng, joalo ka lisebelisoa tse mpe tsa tšepe, ho etsa liforeimi tsa libaesekele, lirimo, li-clamps, li-gaskets, lipoleiti tsa selemo, lisakha le lehare joalo-joalo.

5 Thepa ea mohaho

(1)Rebar

Rebar ke lebitso le tloaelehileng bakeng sa litšepe tse chesang tse halikiloeng, litšepe tse tloaelehileng tse chesang tse halikiloeng ke HRB mme ntlha ea tlhahiso ea eona ea boleng bo tlase e na le H, R, B, ka ho latellana, bakeng sa ho chesa (Hot rolled), e nang le ribbed (Ribbed), rebar (Bars) mantsoe a mararo a lengolo la pele la puo ea Senyesemane. Ho na le tlhokahalo e phahameng ea sebopeho se sebetsang sa litšisinyeho tsa lefatše, se sehlopheng se seng se ntse se lateloa ke tlhaku E (mohlala: HRB400E, HRBF400E)

Lisebelisoa tse ka Sehloohong:Rebar e sebelisoa haholo kahong ea boenjiniere ea sechaba ea matlo, marokho le litsela. E kholo joalo ka litsela tse kholo, liporo, marokho, likotopo, lithanele, taolo ea likhohola, matamo le lisebelisoa tse ling, tse nyane joalo ka motheo oa kaho ea matlo, maballo, litšiea, mabota, lipoleiti, rebar ke thepa ea bohlokoa ea meralo.

(2) terata ea lebelo le phahameng, eo ho thoeng ke "mohala o phahameng", ke mofuta oa molamu oa terata, hangata o bua ka "leloala le lebelo le phahameng le se nang torsion" le ntšitsoeng ka li-coil tse nyane, tse fumanehang ka har'a li-coil tse tloaelehileng tse bonolo tse laoloang tse chesang le tse batang (ZBH4403-88) le li-coil tsa boleng bo holimo tse laoloang ke tšepe. (ZBH4403-88) le boleng bo phahameng ba carbon steel torsion control Hot Rolled Coil (ZBH44002-88) joalo-joalo.

Lisebelisoa tsa mantlha:Mohala o phahameng o sebelisoa haholo likoloing, mechine, kaho, lisebelisoa tsa lapeng, lisebelisoa tsa hardware, indasteri ea lik'hemik'hale, lipalangoang, kaho ea likepe, lihlahisoa tsa tšepe, lihlahisoa tsa lipekere le liindasteri tse ling. Ka ho khetheha, e sebelisoa ha ho etsoa liboutu, linate, li-screws le li-fasteners tse ling, terata ea tšepe ea pele ho khatello, terata ea tšepe e kentsoeng, terata ea tšepe ea selemo, terata ea tšepe e entsoeng ka tšepe joalo-joalo.

(3) Tšepe e chitja

E tsejoang hape e le "bar", ke terata e telele e tiileng e nang le karolo e chitja. Litlhaloso tsa eona ho bophara ba palo ea limilimithara, mohlala: "50" ke hore, bophara ba limilimithara tse 50 tsa tšepe e chitja. Tšepe e chitja e arotsoe ka mefuta e meraro ea ho chesa, e ferekaneng le e huloang ke serame. Tlhaloso ea tšepe e chitja e chesang ke 5.5-250 mm.

Lisebelisoa tse kholo:Limilimithara tse 5.5-25 tsa tšepe e chitja e nyane hangata li fanoa ka bongata ba mekoallo e otlolohileng, e sebelisoang hangata bakeng sa rebar, liboutu le likarolo tse fapaneng tsa mochini; e kholo ho feta limilimithara tse 25 tsa tšepe e chitja, e sebelisoang haholo ha ho etsoa likarolo tsa mochini kapa bakeng sa seamless tšepe pipe billet.

6 Profaele ea tšepe

(1)Libaka tsa tšepe tse bataletseng ke bophara ba 12-300 limilimithara, 4-60 limilimithara botenya, sefapano se khutlonnetsepa 'me hanyenyane ka bohale bo hloekileng ba tšepe, ke mofuta oa profil.

Lisebelisoa tse kholo:Tšepe e bataletseng e ka etsoa tšepe e phethiloeng, e sebelisoang ho hlahisa tšepe ea hoop, lisebelisoa le likarolo tsa mochini, tse sebelisoang kahong e le likarolo tsa sebopeho sa foreimi. E ka boela ea sebelisoa e le thepa e mpe ea phala e cheselitsoeng le e mpe ea poleiti e tšesaane bakeng sa lakane e phuthetsoeng. Litšepe tse bataletseng tsa selemo li ka boela tsa sebelisoa ho kopanya liliba tsa makhasi a koaletsoeng ka koloing.

(2) karolo ea lisekoere ea tšepe, e chesang e kolobisitsoeng le e batang (e batang e huloang) lihlopha tse peli, lihlahisoa tse tloaelehileng ho tse ngata tse batang. Bolelele ba mahlakoreng a tšepe e kolobisitsoeng ka kakaretso ke 5-250 mm. Sebetsa sa boleng bo phahameng ba carbide hlobo, boholo ba sebaka se senyenyane empa se boreleli, ho nepahala ho phahameng, bolelele ba lehlakore ka 3-100 mm.

Lisebelisoa tse ka Sehloohong:E phuthetsoe kapa e entsoe ka tšepe ea lisekoere. E sebelisoa haholo ha ho etsoa mechini, ho etsa lisebelisoa le hlobo, kapa ho lokisa likarolo tse ling. Haholo-holo serame se huleloang holim'a tšepe se setle, se ka sebelisoa ka kotloloho, joalo ka ho fafatsa, ho etsa lehlabathe, ho kobeha, ho cheka, empa hape le ho rala ka kotloloho, ho tlosa nako e ngata ea machining le ho boloka litšenyehelo tsa ho lokisa mochini o sebetsang!

(3)kanale tšepeke karolo ea sefapano bakeng sa tšepe e telele e bōpehileng joaloka groove, tšepe e tloaelehileng ea kanale e kolobisitsoeng ka mokhoa o batang le tšepe ea kanale e bobebe. Litlhaloso tsa tšepe tse tloaelehileng tsa kanale tse futhumetseng bakeng sa 5-40 #, ka phepelo le tumellano ea lehlakore la tlhokeho ho fana ka litlhaloso tsa tšepe tse feto-fetohang tse feto-fetohang bakeng sa 6.5-30 #; serame se entsoeng ka kanale tšepe ho ea ka sebōpeho sa tšepe e ka aroloa ka mefuta e mene: batang-bopehileng lekanang-bohale kanale, batang-bōpehileng ka se leka-lekaneng kanale, batang ka hare ho bohale ba kanale, batang-bopehile ka ntle ho bohale ba kanale.

Tšebeliso e ka sehloohong: Channel ea tšepee ka sebelisoa e le mong, tšepe ea mocha e atisa ho sebelisoa hammoho le I-beam. E sebelisoa haholo-holo ho etsa mohaho oa tšepe oa mohaho, tlhahiso ea likoloi le mehaho e meng ea indasteri.

(4)Angle tšepe, eo ka tloaelo e tsejoang e le angle iron, ke lesela le lelelele la tšepe le nang le mahlakore a mabeli a perpendicular ho e mong ka sebōpeho sa angle. Angle ke ea kaho ea k'habone sebopeho tšepe, ke e bonolo cross-karolo ea karolo tšepe, ka tšebeliso ea ditlhoko tsa molemo weldability, thepa deformation polasetiki le tekanyo e itseng ea matla a mechine. Lisebelisoa tse tala bakeng sa tlhahiso ea tšepe ea angle ke tšepe e tlaase ea carbon square, 'me tšepe e phethiloeng ea angle e chesang e kolobisitsoe ebile e bōpehile.

Lisebelisoa tse kholo:Angle tšepe e ka thehoa ho latela litlhoko tse fapaneng tsa likarolo tse fapaneng tsa tšepe tse hatelitsoeng, e ka sebelisoa hape e le khokahano lipakeng tsa likarolo. Angle steel e sebelisoa haholo meahong e fapaneng ea meaho le meaho ea boenjiniere, joalo ka maballo, liforeimi tsa limela, marokho, litora tsa phetiso, mochini o phahamisang le oa lipalangoang, likepe, libono tsa indasteri, litora tsa karabelo, liraka tsa lijana le lishelefo tsa polokelo.

7 phala

Peipi ea tšepe e cheselitsoengHo thoeng ke phala e cheselitsoeng, e entsoe ka poleiti ea tšepe kapa mohala oa tšepe ka mor'a hore e kobehe le ho bōptjoa, ebe e chesetsoa. Ho ea ka mofuta oa seam welded e arotsoe ka mefuta e 'meli e otlolohileng seam welded phala le spiral welded phala. Ka kakaretso, peipi e cheselitsoeng, e fetisetsoa ho mefuta ena e 'meli ea karolo e chitja e sekoti ea phala ea tšepe, phala e' ngoe e seng chitja ea tšepe e tsejoa e le phala e bōpehileng.

Pipe ea tšepe ho khatello ea metsi, ho khumama, ho batalla le liteko tse ling, ho na le litlhoko tse itseng holim'a boleng bo holimo, bolelele bo tloaelehileng ba ho fana ka 4.10m, hangata bo hloka ho fana ka maoto a tsitsitseng (kapa a mabeli). Welded phala ho ea ka boletsweng lerako botenya ba tloaelehileng tšepe phala le thickened tšepe phala mefuta e 'meli ea tšepe phala ho ea ka mofuta oa phala qetellong e arotsoe ka mefuta e' meli ea le threaded buckle le ntle threaded buckle, tsoela pele rala ho feta le threaded buckle.

Lisebelisoa tse ka Sehloohong:Ho ea ka tšebeliso ea hangata arotsoe ka kakaretso mokelikeli lipalangoang welded phala (peipi ea metsi), galvanized welded phala, oksijene letsa welded phala, terata casing, rolara phala, tebileng hantle pompo phala, phala likoloi (khara shaft phala), phala transformer, tjheseletsa motlakase tšesaane-mabota phala, motlakase tjheseletsa e bōpehileng joaloka phala, joalo-joalo.

Spiral welded phala matla ka kakaretso e phahame ho feta seam o otlolohileng welded phala, ka sebelisa billet moqotetsane ho hlahisa bophara e khōloanyane ea phala tjheseletsa, empa hape le bophara bo tšoanang ba billet ho hlahisa bophara fapaneng ya phala welded. Leha ho le joalo, ha ho bapisoa le bolelele bo lekanang ba phala e otlolohileng ea seam welded, bolelele ba weld bo eketseha ka 30-100%, 'me lebelo la tlhahiso le batla le le tlase. Ka hona, liphaephe tse nyenyane tse cheselitsoeng ka bophara li atisa ho chesetsoa ka ho otloloha ha seam, ha bophara bo boholo ba liphaephe tse cheselitsoeng hangata li cheselitsoe ke spiral welding.

Lisebelisoa tse ka Sehloohong:SY5036-83 e sebelisoa haholo ho tsamaisa oli, liphaephe tsa khase ea tlhaho, SY5038-83 e nang le mokhoa o phahameng oa maqhubu a marang-rang a marang-rang a marang-rang a marang-rang a marang-rang a phahameng a maqhubu a tšepe a tsamaisang metsi a hatelitsoeng, phala ea tšepe e nang le khatello, polasetiki e ntle, e bonolo ho tjheseletsa le ho sebetsa ka mokhoa o ikemetseng3030 le othomathike 30-730 le othomathike. tjheseletsa, kapa mokgwa wa ho tjheseletsa ka lehlakore le le leng bakeng sa ho tsamaisa metsi, kgase, moya le mouoane, le maro a mang a kgatello e tlase ka kakaretso. Mokelikeli.

(3)Peipi e khutlonnetsepake phala ea tšepe e nang le mahlakoreng a lekanang (bolelele ba mahlakoreng ha bo lekane ke phala ea lisekoere tse kgutlonnehile), ke lesela la tšepe ka mor'a ho phutholloa, phekolo ea ts'ebetso ebe e batalatsa, e phuthetsoe, e kolobisitsoe ho theha tube e chitja, ebe e phuthoa ho tloha ka tube e chitja ho kena tube ea lisekoere.

Lisebelisoa tse kholo:Boholo ba li-square tube ke tube ea tšepe, ho feta bakeng sa square tube ea sebopeho, mekhabiso ea square tube, tube ea kaho ea lisekoere, joalo-joalo.

8 e koahetsoe

(1)letlapa la masenkelegalvanized//

Ke poleiti ea tšepe e nang le lesela la zinki ka holim'a metsi, tšepe ea galvanized ke mokhoa o tloaelehileng o sebelisoang, o bolokang chelete e ngata oa ho thibela ho bola. Letlapa la galvanized lilemong tsa pele le ne le sebelisetsoa ho bitsoa "tšepe e tšoeu". Boemo ba ho pepa bo arotsoe ka mefuta e 'meli: e phuthoa le e bataletseng.

Lisebelisoa tse ka Sehloohong:Letlapa le chesang la galvanized le arotsoe ka lakane e chesang-dip le lakane ea elektro-galvanized ho latela mokhoa oa tlhahiso. Letlapa la seseti se chesang-dip le na le lesela le letenya la zinki mme le sebelisetsoa ho etsa likarolo tse hanyetsanang le kutu haholo bakeng sa tšebeliso e bulehileng. Botenya ba zinki lesela la masenke a motlakase bo tšesaane ebile bo tšoana, 'me bo sebelisoa haholo ho penta kapa ho etsa lihlahisoa tsa kahare.

(2)Coil e koahetsoeng ka mebala

Mmala coil coil e chesang galvanized lakane, chesang aluminized zinki poleiti, galvanized lakane motlakase bakeng sa substrate, ka mor'a hore holim'a pretreatment (degreasing lik'hemik'hale le phekolo ea ho fetola lik'hemik'hale), holim'a likarolo tse le 'ngoe kapa ho feta tsa pente ea manyolo, e lateloa ke ho baka le ho phekola sehlahisoa. E boetse e koahetsoe ka mefuta e fapaneng ea mebala e fapaneng ea coil ea tšepe e mebala-bala ea pente, ka hona lebitso, le bitsoang coil e tlotsitsoeng ka mebala.

Lisebelisoa tsa mantlha:Indastering ea kaho, marulelo, mehaho ea marulelo, mamati a phuthoang, li-kiosks, li-shutter, mamati a balebeli, matlo a literateng, likotopo tsa moea, joalo-joalo; indasteri ea thepa ea ka tlung, lihatsetsi, li-air-conditioning, litofo tsa elektroniki, matlo a mochini o hlatsoang liaparo, litofo tsa petroleum, joalo-joalo, indasteri ea lipalangoang, siling ea likoloi, liboto tse ka morao, li-hoardings, likhetla tsa likoloi, literekere, likepe, liboto tsa likoloi joalo-joalo. Har'a lisebelisoa tsena, tse sebelisoang haholo ke fektheri ea tšepe, fektheri e entsoeng ka likarolo tse ngata, fektheri ea tšepe ea mebala.

Nako ea poso: Dec-12-2023