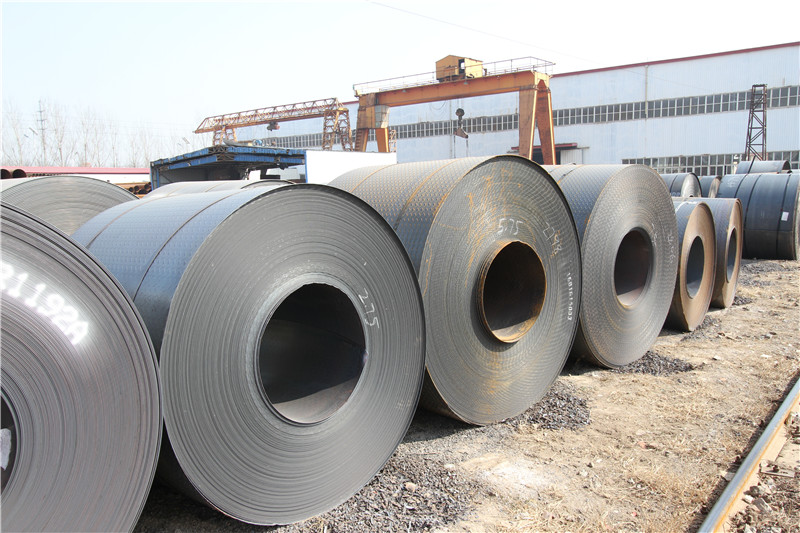

1 Hot Rolled Plate/Hot Rolled Sheet/Inopisa Yakakungurutswa Simbi Coil

Inopisa yakakungurutswa coil inowanzo sanganisira yepakati-ukobvu yakafara simbi tambo, inopisa yakakungurutswa yakatetepa yakafara simbi tambo uye inopisa yakakungurutswa yakatetepa ndiro. Medium-thickness wide simbi tambo ndeimwe yeanonyanya kumiririra marudzi, uye kugadzirwa kwayo kwakaverengera zvingangoita zviviri muzvitatu zveiyo yakazara kuburitsa coil inopisa. Medium-ukobvu yakafara simbi tambo zvinoreva ukobvu ≥3mm uye <20mm, upamhi ≥600mm; inopisa yakakungurutswa yakatetepa yakafara simbi tambo inoreva ukobvu <3mm, hupamhi ≥600mm; inopisa yakakungurutswa ndiro yakatetepa zvinoreva bepa rimwe chete resimbi rine ukobvu <3mm.

Mashandisirwo Akanyanya:Kupisa yakakungurutswa coilzvigadzirwa zvine simba rakawanda, kusimba kwakanaka, nyore kugadzirisa uye kuumba uye yakanaka weldability uye zvimwe zvakanakisa zvivakwa, zvinoshandiswa zvakanyanya muchando chakakungurutswa substrates, ngarava, mota, mabhiriji, kuvaka, michina, mapaipi emafuta, midziyo yekumanikidza uye mamwe maindasitiri ekugadzira.

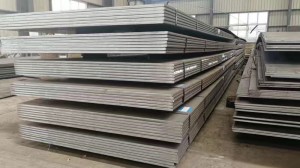

2 Cold Rolled Sheet/Cold Rolled Coil

Cold rolled sheet uye coil icoil inopisa yakakungurutswa seyakabikwa, yakakungurutswa patembiricha yepakamuri pazasi petembiricha yerecrystallization, kusanganisira ndiro uye coil. Imwe yekutakura pepa inonzi simbi ndiro, inozivikanwawo sebhokisi kana furati ndiro, kureba kwakareba, iyo coil kuendesa inonzi simbi strip inozivikanwawo se coil. Ukobvu 0.2-4mm, hupamhi 600-2000mm, kureba 1200-6000mm.

Mashandisirwo Akanyanya:Cold rolled steel stripine zvakawanda zvekushandisa, sekugadzira mota, zvigadzirwa zvemagetsi, rolling stock, aviation, precision instrumentation, chikafu canning nezvimwe zvakadaro. Cold plate inogadzirwa kubva kune yakajairwa kabhoni structural simbi inopisa yakakungurutswa simbi tambo, mushure mekuwedzera kutonhora kukungurutswa kwakaitwa nesimbi ndiro ukobvu isingasviki 4mm. Sezvo yakakungurutswa patembiricha yekamuri, haiburitse iron oxide, inotonhora yeplate pamusoro pemhando, yakakwirira dimensional kurongeka, yakasanganiswa neannealing, michina yayo uye maitiro ekugadzira zviri nani pane inopisa-yakakungurutswa pepa, munzvimbo dzakawanda, kunyanya mundima yekugadzira mudziyo wemba, yave kushandiswa zvishoma nezvishoma kutsiva inopisa-yakakungurutswa shiti.

3 ndiro gobvu

Plate yepakati inoreva kukora kwe3-25mm simbi ndiro, ukobvu hwe25-100mm hunonzi gobvu ndiro, ukobvu hunodarika 100mm kune yakawedzera gobvu ndiro.

Mashandisirwo Akanyanya:Medium-gobvu ndiro inonyanya kushandiswa mukuvaka engineering, kugadzira michina, kugadzira midziyo, kuvaka ngarava, kuvaka bhiriji uye zvichingodaro. Inoshandiswa kugadzira zvakasiyana-siyana zvemidziyo (kunyanya midziyo yekumanikidza), mabhodhoro ebhailer uye zvimiro zvemabhiriji, pamwe nechimiro chemotokari danda, rwizi uye gungwa zvikepe zvekutakura zvikepe, zvimwe zvikamu zvemuchina, zvinogona zvakare kuunganidzwa uye kusungirirwa muzvikamu zvikuru.

Strip simbi nenzira yakafara inoreva coil yese senzvimbo yekutumira, kureba kwesimbi yakati sandara yakareba. Narrowly inoreva hupamhi hwakatetepa hwecoil, kureva, inowanzonzi simbi yakamanikana uye yepakati uye yakafara strip simbi, dzimwe nguva kunyanya nhete strip simbi. Zvinoenderana neNational Statistical classification index, iyo coil iri pazasi 600mm (kusanganisa 600mm) yakamanikana tambo kana nhete strip simbi. 600 mm uye pamusoro pakafara tambo.

Mashandisirwo Akanyanya:Strip simbi inonyanya kushandiswa muindasitiri yemotokari, indasitiri yekugadzira michina, kuvaka, simbi chimiro, zuva nezuva-kushandisa Hardware uye mamwe minda, sekugadzira welded simbi pombi, seyakatonhora-yakaumbwa simbi yakaipa zvinhu, kugadzira bhasikoro mafuremu, marimu, clamps, gaskets, chitubu ndiro, masaha uye razor blades uye zvichingodaro.

5 Zvinhu zvekuvaka

(1)Rebar

Rebar izita rakajairika remasimbi anopisa akakungurutswa, akajairwa anopisa akakungurutswa simbi neHRB uye giredhi rayo goho poindi yehushoma kukosha kwegiredhi rine H, R, B, zvichiteerana, kune inopisa yakakungurutswa (Hot rolled), ine ribbed (Ribbed), rebar (Mabhara) iwo mazwi matatu ebhii rekutanga remutauro weChirungu. Pane chinodiwa chepamusoro cheiyo seismic chimiro chinoshanda giredhi, iri mugiredhi riripo rinoteverwa nebhii E (semuenzaniso: HRB400E, HRBF400E)

Zvishandiso Zvikuru:Rebar inoshandiswa zvakanyanya mukuvaka engineering yekuvaka dzimba, mabhiriji nemigwagwa. Yakakura semigwagwa mikuru, njanji, mabhiriji, makombi, tunnel, kudzora mafashama, madhamu uye zvimwe zvinoshandiswa, zvidiki senheyo yekuvaka dzimba, matanda, makoramu, madziro, marata, rebar chinhu chakakosha chiumbwa.

(2) high-speed waya tsvimbo, inonzi "high line", imhando yetambo yewaya, inowanzoreva "high-speed torsion-free mill" yakakungurutswa kubva mumakoiri maduku, anowanzo kuwanikwa musimbi yakapfava-inodzorwa inopisa uye inotonhora yakamonerwa coils (ZBH4403-88) uye high-quality controlled carbon horted (ZBH4403-88) uye yepamusoro-soro carbon steel torsion control Hot Rolled Coil (ZBH44002-88) nezvimwe zvakadaro.

Main Applications:Waya yakakwirira inoshandiswa zvakanyanya mumotokari, michina, kuvaka, midziyo yemumba, maturusi emidziyo, indasitiri yemakemikari, chekufambisa, kuvaka ngarava, zvigadzirwa zvesimbi, zvigadzirwa zvembambo uye mamwe maindasitiri. Kunyanya, inoshandiswa mukugadzira mabhaudhi, nzungu, screws uye zvimwe fasteners, pre-stressing simbi waya, stranded simbi waya, chitubu simbi waya, galvanized simbi waya uye zvichingodaro.

(3) Simbi yakatenderera

inozivikanwawo se "bha", ibhawa refu rakasimba rine denderedzwa remuchinjikwa-chikamu. Tsanangudzo dzayo kune dhayamita yehuwandu hwemamirimita, semuenzaniso: "50" kureva, dhayamita ye50 millimeters yesimbi yakatenderedza. Simbi yakatenderedzwa yakakamurwa kuita inopisa-yakakungurutswa, yefodhi uye inotonhora-inodhonzwa mhando nhatu. Kutsanangurwa kwesimbi inopisa yakatenderedzwa ndeye 5.5-250 mm.

Main kushandiswa:5.5-25 millimeters ediki raundi simbi inonyanya kupihwa mumasumbu emabhawa akatwasuka, anowanzoshandiswa rebar, mabhoti uye akasiyana emakanika zvikamu; yakakura kupfuura mamirimita makumi maviri nemashanu esimbi yakatenderedzwa, inonyanya kushandiswa mukugadzira zvikamu zvemakanika kana yesimbi isina musono pombi billet.

6 Steel Profile

(1)Flat Steel Bars iri 12-300 mm yakafara, 4-60 mm gobvu, rectangular cross-section uye zvishoma ine yakachena mupendero wesimbi, imhando yeprofile.

Main kushandiswa:Simbi yakatsetseka inogona kugadzirwa kuita simbi yakapedzwa, inoshandiswa mukugadzira hoop iron, maturusi uye zvikamu zvemuchina, zvinoshandiswa mukuvaka senge furemu yezvimiro zvikamu. Inogona zvakare kushandiswa sechinhu chakashata chepombi yakasungwa uye yakaipa yendiro yakatetepa yepepa rakaturikidzana. Spring flat simbi inogona zvakare kushandiswa kuunganidza mota yakaturikidzana mashizha zvitubu.

(2) chikamu chesikweya chesimbi, inopisa yakakungurutswa uye inotonhora yakakungurutswa (inotonhora inodhonzwa) mapoka maviri, zvakajairika zvigadzirwa kune inotonhora inokweverwa ruzhinji. Kupisa yakakungurutswa sikweya sikweya kureba kunowanzo 5-250 mm. inotonhora inodhonzwa sikweya simbi yekushandisa yepamusoro-yemhando carbide mold processing, saizi yeimwe diki asi yakatsetseka pamusoro, yakakwira chaiyo, kureba kweparutivi mu3-100 mm.

Mashandisirwo Akanyanya:Yakakungurutswa kana kugadzirwa kuita square cross-section simbi. Inonyanya kushandiswa mukugadzira michina, kugadzira maturusi uye mold, kana kugadzirisa masipire. Kunyanya inotonhora inodhonzwa simbi yepasi mamiriro yakanaka, inogona kushandiswa zvakananga, sekupfapfaidza, jecha, kukotama, kuchera, asiwo yakananga plating, kubvisa yakawanda yenguva yekugadzira uye kuchengetedza mutengo wekugadzirisa mashini ekugadzirisa!

(3)channel simbindiyo muchinjiko-chikamu chegorofu-yakaita simbi refu, inopisa-yakakungurutswa yakajairika chiteshi simbi uye inotonhora-yakaumbwa lightweight chiteshi simbi. Kupisa-yakakungurutswa yakajairwa chiteshi simbi inotsanangurwa ye5-40 #, nekupa uye kudiwa kwedivi chibvumirano chekupa inopisa-yakakungurutswa inochinja-chinja chiteshi simbi yakatarwa ye6.5-30 #; inotonhora-yakaumbwa mugero simbi maererano nechimiro chesimbi inogona kukamurwa kuita mhando ina: inotonhora-yakaumbwa yakaenzana-kumucheto chiteshi, inotonhora-yakaumbwa isina kuenzana chiteshi, inotonhora-yakaumbwa mukati memucheto wegwara, inotonhora-yakaumbwa kunze kwemucheto kwegwara.

Kunyanya kushandiswa: Steel Channelinogona kushandiswa yoga, chiteshi chesimbi chinowanzoshandiswa pamwe chete neI-beam. Inonyanya kushandiswa kugadzira chivakwa chesimbi, kugadzira mota uye zvimwe zvimiro zveindasitiri.

(4)angle simbi, inowanzozivikanwa sesimbi yemakona, itambo refu yesimbi ine mativi maviri akananga kune rimwe nerimwe muchimiro chekona. Angle ndeyekuvakwa kwekabhoni structural simbi, iri nyore muchinjiko-chikamu chechikamu chesimbi, mukushandiswa kwezvinodiwa zvezvakanaka weldability, epurasitiki deformation zvivakwa uye imwe dhigirii yesimba remagetsi. Iyo mbishi simbi yekugadzirwa kwekona simbi yakaderera kabhoni square simbi, uye yakapedzwa kona simbi inopisa yakakungurutswa uye yakaumbwa.

Main kushandiswa:Angle simbi inogona kuumbwa zvinoenderana nezvinodiwa zvakasiyana zvezvakasiyana zvakasiyana zvakasimbiswa simbi zvikamu, zvinogona zvakare kushandiswa sechibatanidza pakati pezvikamu. Angle simbi inoshandiswa zvakanyanya mumhando dzakasiyana dzezvivakwa zvekuvaka uye zvivakwa zveinjiniya, senge matanda, mapuranga emiti, mabhiriji, shongwe dzekutapurirana, kusimudza uye kutakura michina, ngarava, mavira indasitiri, shongwe dzekuita, maraki emidziyo uye masherufu ekuchengetera zvinhu.

7 pombi

Welded simbi pombiinonzi welded pombi, inogadzirwa nesimbi ndiro kana simbi tambo mushure mekukotama uye kuumbwa, uye wozoiswa weld. Maererano chimiro welded musono rakakamurwa mhando mbiri dzakatwasuka musono welded pombi uye spiral welded nyere. Kazhinji kutaura, iyo welded pombi, dzinotaurwa kune idzi mhando mbiri dzegomba denderedzwa chikamu chepombi yesimbi, imwe isiri-denderedzwa pombi yesimbi inozivikanwa sepombi yakaumbwa.

Simbi pombi kudzvinyiriro yemvura, kupeta, kubata kumeso uye zvimwe zviedzo, pane zvimwe zvinodikanwa pamhando yepamusoro, iyo yakajairwa kureba yekutakura ye4.10m, kazhinji inoda yakamisikidzwa-tsoka (kana kaviri-tsoka) kuendesa. Welded pombi zvinoenderana neyakatsanangurwa madziro ukobvu hweyakajairika simbi pombi uye gobvu simbi pombi marudzi maviri esimbi pombi zvinoenderana nechimiro chepombi yekupedzisira yakakamurwa kuita marudzi maviri ane shinda yakarukwa bhandi uye isina tambo yakasungwa, inoenderera ichiisa yakawanda neshinda yakarukwa.

Mashandisirwo Akanyanya:Maererano kushandiswa kazhinji kupatsanurwa mukuru fluid chokufambisa welded nyere (mvura mutopota), kwakakurudzira welded nyere, okisijeni kuridza welded nyere, waya casing, roller nyere, yakadzika tsime pombi nyere, motokari nyere (notyaira mugodhi nyere), transformer nyere, yemagetsi welding dzakatetepa-rusvingo pombi, yemagetsi welding yakaita nyere, zvichingodaro.

(2)spiral pombi

Spiral welded pombi simba rinowanzo kukwirira kupfuura yakatwasuka seam welded pombi, inogona kushandisa yakamanikana billet kuburitsa yakakura dhayamita yepombi yakashongedzwa, asiwo nehupamhi hwakafanana hwebillet kuti ibudise dhayamita yakasiyana yepombi yakasungwa. Zvisinei, kana zvichienzaniswa nehurefu hwakafanana hwemusono wakanyoroveswa pombi, kureba kweweld kunowedzera ne30-100%, uye kukurumidza kwekugadzira kwakaderera. Naizvozvo, dhayamita diki welded pombi dzinonyanya kurumwa nechakatwasuka seam welding, nepo hombe dhayamita yakashongedzwa pombi dzinonyanya kuputika ne spiral welding.

Zvishandiso Zvikuru:SY5036-83 inonyanya kushandiswa kutakura oiri, gasi pombi, SY5038-83 ine yakakwira-frequency lap welding nzira yakakwenenzverwa spiral seam yakakwirira-frequency welded simbi pombi yekufambisa yemvura yakamanikidzwa, iyo simbi pombi inomanikidza-inotakura simba, yakanaka plasticity, iri nyore kubatanidza uye kugadzika 30 uye kuumbwa SYM30 otomatiki 30 uye molding 7 side. welding, kana imwe-sided welding nzira yekufambisa kwemvura, gasi, mhepo uye chiutsi, uye mamwe akadzika-kudzvinyirira zvinwiwa zvakajairika. Fluid.

(3)Rectangular pipeinyere yesimbi ine mativi akaenzana (kurutivi kureba hakuna kuenzana is square rectangular pombi), itambo yesimbi mushure mekudzura, process treatment yobva yaita flatten, curled, welded kuita round chubhu, yobva yakungurutswa kubva paround chubhu kuita square chubhu.

Main kushandiswa:Yakawanda yeskweya chubhu ichubhu yesimbi, yakawanda yekumisikidza square chubhu, yekushongedza square chubhu, yekuvaka square chubhu, nezvimwe.

8 yakavharwa

(1)galvanized sheetuyegalvanized coil

Indiro yesimbi ine dhizaini ye zinc pamusoro, simbi yemarara inowanzoshandiswa, inodhura-inoshanda anti-corrosion nzira. Galvanized sheet mumakore ekutanga raishandiswa kunzi "white iron". Mamiriro ekutumira akakamurwa kuva marudzi maviri: akakungurutswa uye flat.

Mashandisirwo Akanyanya:Pepa rinopisa-dhip rakakamurwa kuita rinopisa-dhip galvanized sheet uye electro-galvanized sheet zvinoenderana nemaitiro ekugadzira. Pepa rinopisa-dip rine zinc layer yakakora uye rinoshandiswa kugadzira zvidimbu zvisingaite ngura kuitira kushandiswa pamhepo. Ukobvu hwezinc layer yemagetsi galvanized sheet itete uye yunifomu, uye inonyanya kushandiswa kupenda kana kugadzira zvigadzirwa zvemukati.

Rudzi rwakaputirwa coil inopisa pepa rakabatiswa, rinopisa aluminized zinc ndiro, yemagetsi galvanized sheet for the substrate, mushure mekugadzirwa kwepamusoro (chemical degreasing uye kemikari kutendeuka kurapwa), pamusoro peimwe kana anopfuura akaturikidzana eorganic pendi, inoteverwa nekubika uye kurapa kwechigadzirwa. Yakaputirwawo neakasiyana emhando dzakasiyana dze organic pendi ine ruvara rwesimbi coil, saka zita, rinodaidzwa kuti coil coil coil.

Main Applications:Muindasitiri yekuvaka, matenga, zvivakwa zvedenga, magonhi ekukungurusa, makioski, zvivharo, magonhi evarindi, pekugara mumigwagwa, madhiri emhepo, nezvimwe; indasitiri yefenicha, mafiriji, maair-conditioning units, zvitofu zvemagetsi, dzimba dzemuchina wokuwachira, zvitofu zvepetroleum, nezvimwewo, indasitiri yezvekufambisa, sirin’i dzemotokari, mabhodhi ekumashure, mahodhi, mabhomba emotokari, matirakita, ngarava, mabhodhi emubhankere zvichingodaro. Pakati pezvishandiso izvi, iyo inonyanya kushandiswa isimbi fekitori, composite panel fekitori, ruvara rwesimbi tile fekitori.

Nguva yekutumira: Zvita-12-2023