Color coated plate PPGI/PPGL is a combination of steel plate and paint, so is its thickness based on the thickness of the steel plate or on the thickness of the finished product?

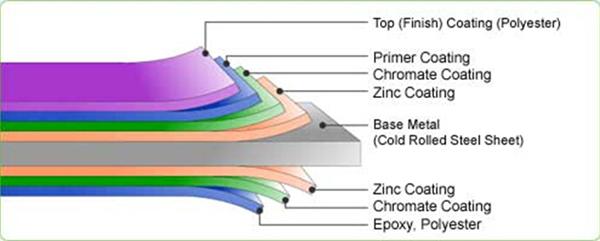

First of all, let's understand the structure of color coated plate for construction:

There are two ways to express the thickness of PPGI/PPGL

First, the finished thickness of color coated plate

For example: finished thickness of 0.5mm color coated sheet, paint film thickness of 25/10 microns

Then we can think of color coated substrate (cold rolled sheet + galvanized layer thickness, chemical conversion layer thickness can be ignored) thickness is 0.465mm.

Common 0.4mm, 0.5mm, 0.6mm color coated sheet, that is, the total thickness of the finished product, which is more convenient for us to measure directly.

Second, the customer specified requirements of color coated substrate thickness

For example: the substrate thickness of 0.5mm color coated plate, paint film thickness of 25/10 microns

Then the thickness of the finished product is 0.535mm, if you need to cover the PVC film to protect the board surface, we need to add the thickness of the film, from 30 to 70 microns.

Finished product thickness = color coated substrate (cold rolled sheet + galvanized layer) + paint film (top paint + back paint) + PVC film

The above case difference of 0.035mm, we see that in fact it is a very small gap, but in the use of customer demand should also be very careful. Therefore, when ordering, please inform the demand in detail.

How to select the color of color coated coil

Color coated plate coating color selection: the choice of color is mainly to consider the match with the surrounding environment and the user's hobby, but from the point of view of the use of technology, light-colored coatings of pigments to choose a large margin of choice, you can choose superior durability of the inorganic pigments (such as titanium dioxide, etc.), and the coating's thermal reflectivity (reflection coefficient of the dark coatings up to double the summer coating itself is relatively low, which is to extend the life of the coating This is beneficial to the extension of coating life.

Post time: Dec-15-2024