Steel sheet pile is a kind of reusable green structural steel with unique advantages of high strength, light weight, good water stopping, strong durability, high construction efficiency and small area. Steel sheet pile support is a kind of support method that uses machinery to drive specific types of steel sheet piles into the ground to form a continuous underground slab wall as the foundation pit enclosure structure. Steel sheet piles are prefabricated products that can be transported directly to the site for immediate construction, which is characterized by fast construction speed. Steel sheet piles can be pulled out and reused, featuring green recycling.

sheet piles are mainly divided into six types according to the different section types: U type steel sheet piles, Z type steel sheet piles, straight-sided steel sheet piles, H type steel sheet piles, pipe-type steel sheet piles and AS-type steel sheet piles. During the construction process, it is necessary to choose different section types of steel sheet piles according to the project conditions and cost control characteristics.

U Shape Sheet Pile

Larsen steel sheet pile is a common type of steel sheet pile, its section form shows "U" shape, which consists of a longitudinal thin plate and two parallel edge plates.

Advantages: U-shaped steel sheet piles are available in a wide range of specifications, so that a more economical and reasonable cross-section can be selected according to the actual situation of the project to optimize the engineering design and reduce the construction cost; and the U-shaped cross-section is stable in shape, not easy to be deformed, and it has a strong load-bearing capacity, which can withstand large horizontal and vertical loads, and it is suitable for the fields of deep foundation pit projects and river cofferdams. Shortcomings: U-shaped steel sheet pile requires large piling equipment in the construction process, and the cost of the equipment is high. Meanwhile, due to its special shape, the splicing extension construction is cumbersome and its scope of use is small.

Z Sheet Pile

Z-Sheet Pile is another common type of steel sheet pile. Its section is in the form of "Z", which consists of two parallel sheets and one longitudinal connecting sheet.

Advantages: Z-section steel sheet piles can be extended by splicing, which is suitable for projects requiring longer lengths; the structure is compact, with good water tightness and seepage resistance, and is more prominent in bending resistance and bearing capacity, which is suitable for projects with larger excavation depths, harder soil layers, or projects that need to withstand large water pressures. Shortcomings: The bearing capacity of steel sheet pile with Z section is relatively weak, and it is easy to be deformed when encountering large loads. As its splices are prone to water leakage, additional strengthening treatment is required.

Right Angle Sheet Pile

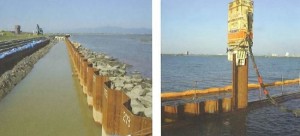

Right-angle steel sheet pile is a kind of steel sheet pile with right-angle structure in section. It usually consists of a combination of two L-type or T-type sections, which can realize greater excavation depth and stronger bending resistance in some special cases. Advantages: Steel sheet piles with right-angle section have strong bending resistance and are not easily deformed when encountering large loads. Meanwhile, it can be disassembled and reassembled several times, which is more flexible and convenient in the construction process, and is suitable for marine engineering, offshore dykes and wharves. Shortcomings: Steel sheet piles with right-angle section are relatively weak in terms of compressive capacity, and are not suitable for projects subject to large lateral pressure and extrusion pressure. Meanwhile, due to its special shape, it can't be extended by splicing, which limits its use.

H shape steel sheet pile

Steel plate rolled into H-shape is used as the form of supporting structure, and the construction speed is fast in foundation pit excavation, trench excavation and bridge excavation. Advantages: H-shaped steel sheet pile has larger cross-section area and more stable structure, with higher bending rigidity and bending and shear resistance, and can be disassembled and assembled many times, which is more flexible and convenient in the construction process. Shortcomings: H-shape section steel sheet pile requires larger piling equipment and vibratory hammer, so the construction cost is higher. Moreover, it has special shape and weaker lateral stiffness, so the pile body tends to tilt to the weaker side when piling, which is easy to produce construction bending.

Tubular Steel Sheet Pile

Tubular steel sheet piles are a relatively rare type of steel sheet piles with a circular section made of a thick-walled cylindrical sheet.

Advantage: This type of section gives circular sheet piles good compressive and load carrying capacity, and can perform better than other types of sheet piles in certain specific applications.

Disadvantage: The circular section encounters more lateral resistance of the soil during settlement than the straight section, and is prone to rolled edges or poor sinking when the ground is too deep.

AS type steel sheet pile

With specific cross-section shape and installation method, it is suitable for specially formulated projects, and is more used in Europe and America.

Post time: May-13-2024