laser cutting

At present, laser cutting has been very popular in the market, 20,000W laser can cut the thickness of about 40 thick, just in the cutting of 25mm-40mm steel plate cutting efficiency is not so high, cutting costs and other issues. If the premise of precision is usually used under the premise of laser cutting. At present, laser cutting is the most used cutting method, generally choose to cut thickness between 0.2mm-30mm can choose laser cutting.

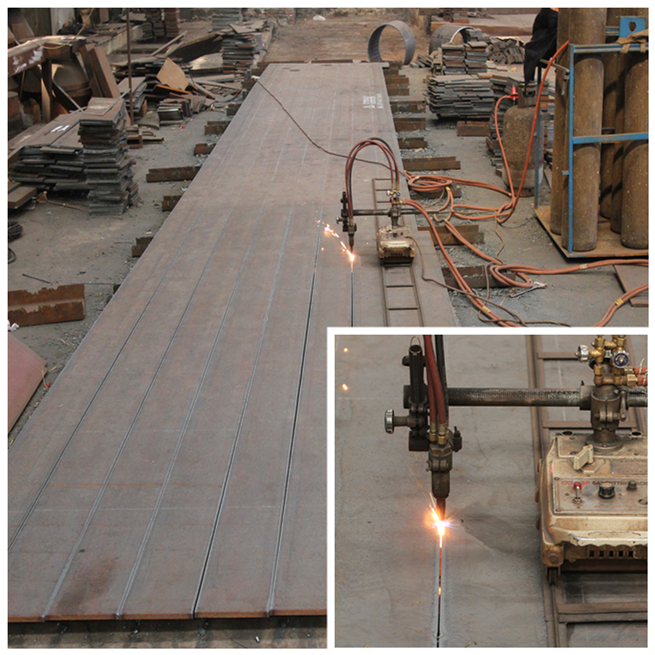

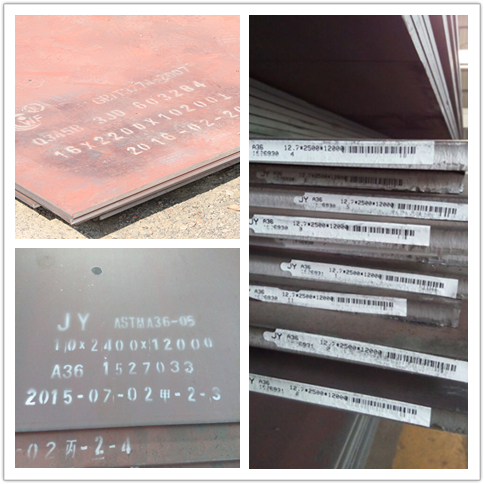

CNC flame cutting

CNC flame cutting is mainly to cut more than 25mm of medium-thick plate, thick plate we use flame cutting, with the continuous development of laser cutting, flame cutting is generally used to cut more than 35mm of steel sheet.

shearing

Shearing is for the requirements of low-cost, cutting precision is not high steel processing, such as embedded steel, gaskets, shearing perforated parts such as the use of shearing.

wire cutting

Water flow cutting, its cutting range, high precision, not easy to deform, more environmentally friendly, but slow, energy consumption, we can choose to cut depending on the situation.

To summarize: there are a variety of methods of steel plate cutting, we can according to the actual situation, from the cost, processing efficiency, processing quality and other perspectives to choose the method of steel plate cutting and processing.

Post time: Feb-29-2024