When the steel plate is hot dipped coating, the steel strip is pulled from the zinc pot, and the alloy plating liquid on the surface crystallizes after cooling and solidification, showing a beautiful crystal pattern of the alloy coating. This crystal pattern is called "zinc Spangles".

How do zinc Spangles form?

Generally speaking, when the steel strip passes through the zinc pot, through the process control, it is managed to generate a large number of crystallization nuclei, reduce the solidification temperature of the zinc liquid, in order to extend the crystallization time of zinc Spangles, and facilitate the control of the growth of zinc Spangles. The size, brightness and surface morphology of zinc Spangles depend on a series of factors, but are mainly related to the composition of zinc layer and cooling method.

zinc Spangles classification

In the world, zinc Spangles are usually divided into regular zinc Spangles and small zinc Spangles.

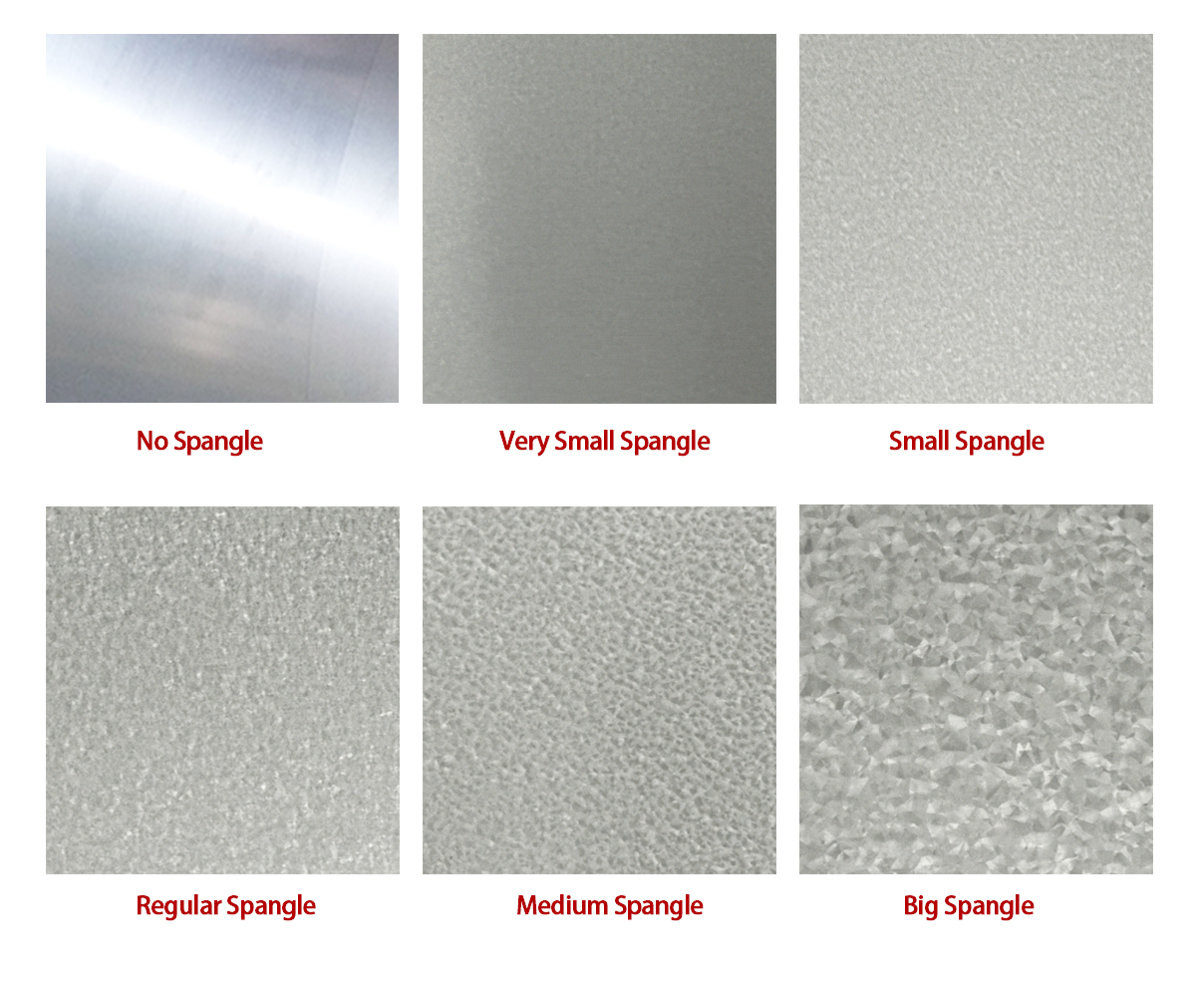

The subdivided zinc Spangles are shown below:

Application

Application

Big zinc Spangles, medium zinc Spangles, regular zinc Spangles are often used in roof tile, beams, large spans and other architectural scenes, its exquisite technology and unique zinc Spangles patterns, add a lot of color to the building. Whether it is hot summer or cold winter, its excellent corrosion resistance enables it to maintain a new appearance for a long time without frequent maintenance.

Small zinc Spangles are mostly used in electronics, electrical appliances, home appliances and other scenes, they are popular, not only because of their exquisite texture, but also because of their excellent machinability and corrosion resistance, making it an indispensable choice in the field of civilian products. The silver gray color and unique texture of the aluminized zinc Spangles inject a modern sense of high class into the urbanization construction.

Post time: Nov-13-2023