What is Larsen steel sheet pile?

In 1902, a German engineer named Larsen firstly produced a kind of steel sheet pile with U shaped cross-section and locks at both ends, which was successfully applied in engineering, and was called "Larsen Sheet Pile" after his name. Nowadays, Larsen steel sheet piles have been globally recognized and widely used in foundation pit support, engineering cofferdams, flood protection and other projects.

Larsen steel sheet pile is an international common standard, the same type of Lassen steel sheet pile produced in different countries can be mixed in the same project. The product standard of Larsen steel sheet pile has made clear provisions and requirements on the cross-section size, locking style, chemical composition, mechanical properties and inspection standards of the material, and the products have to be strictly inspected at the factory. Therefore, Larsen steel sheet pile has good quality assurance and mechanical properties, and can be used repeatedly as turnover material, which has irreplaceable advantages in ensuring construction quality and reducing project cost.

Types of Larsen steel sheet piles

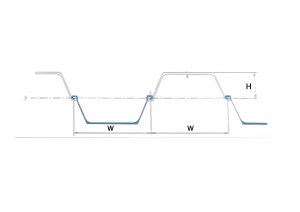

According to different section width, height and thickness, Larsen steel sheet piles can be divided into various models, and the effective width of a single pile of commonly used steel sheet piles mainly has three specifications, namely 400mm, 500mm and 600mm.

The length of Tensile Steel Sheet Pile can be customized and produced according to the project needs, or can be cut into short piles or welded into longer piles after purchase. When it is not possible to transport long steel sheet piles to the construction site due to the limitation of vehicles and roads, the piles of the same type can be transported to the construction site and then welded and lengthened.

Larsen steel sheet pile material

According to the yield strength of the material, the material grades of Larsen steel sheet piles conforming to the national standard are Q295P, Q355P, Q390P, Q420P, Q460P, etc., and those conforming to the Japanese standard are SY295, SY390, etc. Different grades of materials, in addition to their chemical compositions, can also be welded and lengthened. Different grades of materials in addition to different chemical composition, its mechanical parameters are also different.

Commonly used Larsen steel sheet pile material grades and mechanical parameters

|

Standard |

Material |

Yield stress N/mm² |

Tensile strength N/mm² |

Elongation % |

Impact absorption work J(0℃) |

|

JIS A 5523 (JIS A 5528) |

SY295 |

≥295 |

≥490 |

≥17 |

≥43 |

|

SY390 |

≥390 |

≥540 |

≥15 |

≥43 |

|

|

GB/T 20933 |

Q295P |

≥295 |

≥390 |

≥23 |

—— |

|

Q390P |

≥390 |

≥490 |

≥20 |

—— |

Post time: Jun-13-2024