If you do not know how to choose hot rolled plate&coil and cold rolled plate&coil in procurement and use, you can take a look at this article first.

First of all, we need to understand the difference between these two products, and I will briefly explain it for you.

1, Different colors

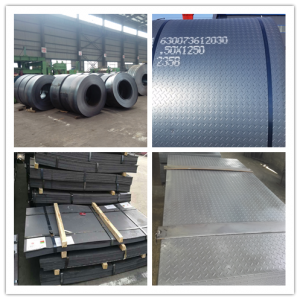

The two rolled plates are different, the cold rolled plate is silver, and the hot rolled plate color is more, some are brown.

2,feel different

Cold rolled sheet feels fine and smooth, and the edges and corners are neat. The hot-rolled plate feels rough and the edges and corners are not neat.

3, Different characteristics

The strength and hardness of cold-rolled sheet are high, and the production process is more complex, and the price is relatively high. The hot-rolled plate has lower hardness, better ductility, more convenient production and lower price.

The advantages of hot rolled plate

1, low hardness, good ductility, strong plasticity, it is easy to process, can be made into various shapes.

2, thick thickness, moderate strength, good bearing capacity.

3, with good toughness and good yield strength, can be used to make spring pieces and other accessories, after heat treatment, can also be used to make many mechanical parts.

Hot-rolled plate is widely used in ships, automobiles, Bridges, construction, machinery, pressure vessels and other manufacturing industries.

The application of cold rolled plate

1. Packaging

The common packaging is iron sheet, lined with moisture-proof paper, and tied with iron waist, which is more secure to avoid friction between the cold rolled coils inside.

2. Specifications and dimensions

The relevant product standards specify the recommended standard lengths and widths of cold-rolled coils and their allowable deviations. The length and width of the volume must be determined according to user requirements.

3, appearance surface state:

The surface state of cold rolled coil is different due to different treatment methods in coating process.

4, galvanized quantity galvanized quantity standard value

Galvanizing quantity indicates the effective method of zinc layer thickness of cold rolled coil, and the unit of galvanizing quantity is g/m2.

Cold-rolled coil is widely used, such as automobile manufacturing, electrical products, rolling stock, aviation, precision instruments, food cans and so on. In many fields, especially in the field of home appliance manufacturing, it has gradually replaced hot-rolled sheet steel.

Post time: Jun-16-2023