Hot Rolled Steel Cold Rolled Steel

1. Process: Hot rolling is the process of heating steel to a very high temperature (usually around 1000°C) and then flattening it with a large machine. The heating makes the steel soft and easily deformable, so it can be pressed into a variety of shapes and thicknesses, and then it is cooled down.

2. Advantages:

Cheap: low manufacturing costs because of the simplicity of the process.

Easy to process: steel at high temperatures is soft and can be pressed into large sizes.

Fast production: suitable for producing large quantities of steel.

3. Disadvantages:

Surface is not smooth: a layer of oxide is formed during the heating process and the surface looks rough.

The size is not precise enough: due to the steel will be expanded when hot rolling, the size may have some errors.

4. Application areas: Hot Rolled Steel Products is commonly used in buildings (such as steel beams and columns), bridges, pipelines and some industrial structural parts, etc., mainly where great strength and durability are required.

Hot rolling of steel

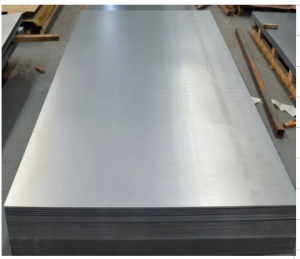

1. Process: Cold rolling is carried out at room temperature. The hot rolled steel is first cooled to room temperature and then further rolled by machine to make it thinner and more precisely shaped. This process is called “cold rolling” because no heat is applied to the steel.

2. Advantages:

Smooth surface: The surface of cold rolled steel is smooth and free of oxides.

Dimensional accuracy: Because the cold rolling process is so precise, the thickness and shape of the steel are very accurate.

Higher strength: cold rolling increases the strength and hardness of the steel.

3. Disadvantages:

Higher cost: cold rolling requires more processing steps and equipment, so it is costly.

Slower production speed: Compared to hot rolling, the production speed of cold rolling is slower.

4. Application: Cold rolled steel plate is commonly used in automobile manufacturing, home appliances, precision machinery parts, etc., which require higher surface quality and precision of steel.

Summarize

Hot rolled steel is more suitable for the production of large-size and high-volume products at lower cost, while cold rolled steel is suitable for applications that require high surface quality and precision, but at a higher cost.

Cold rolling of steel

Post time: Oct-01-2024