Checkered Plate is a decorative steel plate obtained by applying a patterned treatment to the surface of the steel plate. This treatment can be done by embossing, etching, laser cutting and other methods to form a surface effect with unique patterns or textures.

Checkered Steel Plate, also known as embossed plate, is a steel plate with diamond-shaped or protruding ribs on its surface.

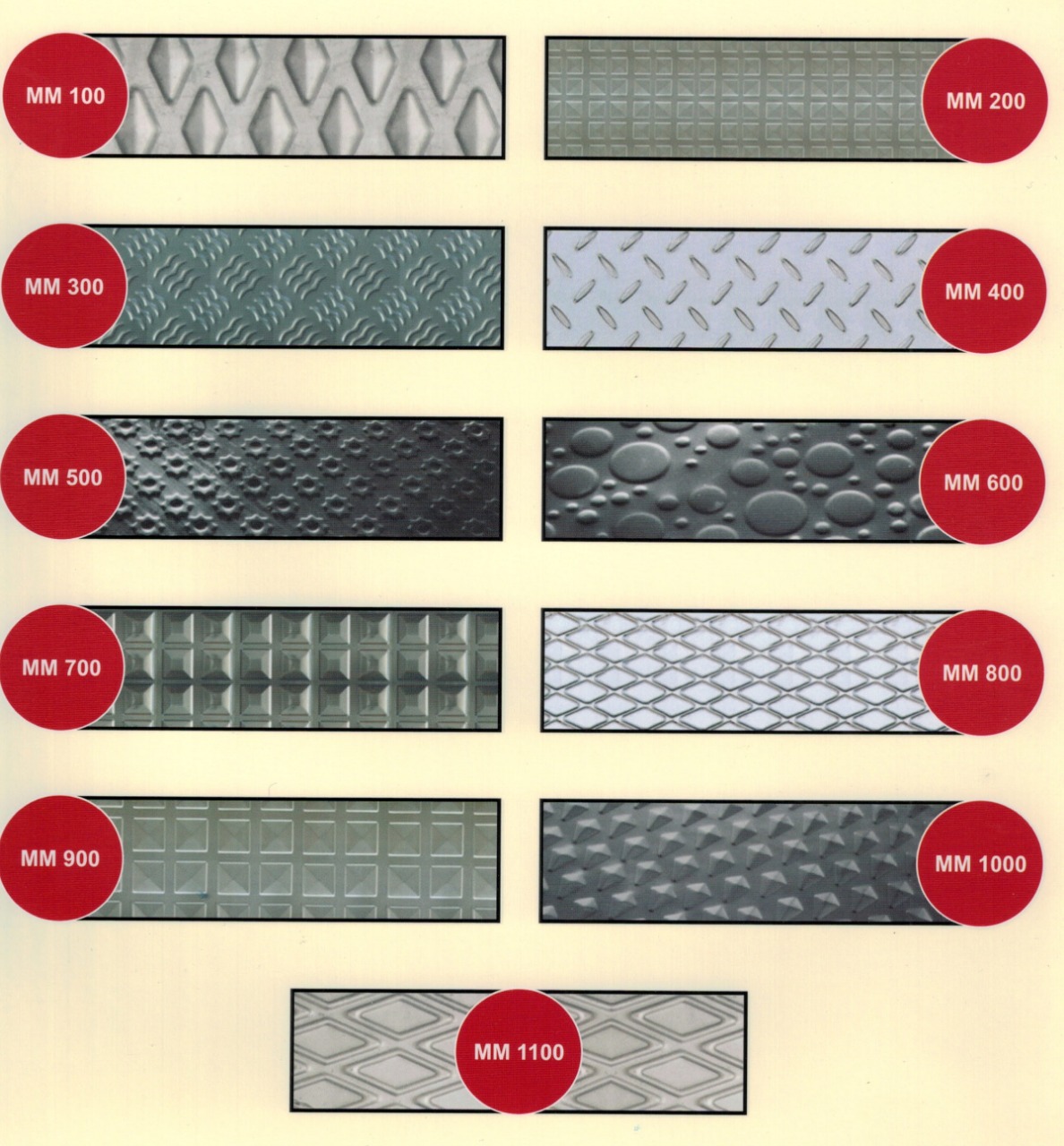

The pattern can be a single rhombus, lentil or round bean shape, or two or more patterns can be properly combined to become a combination of patterned plate.

Patterned steel manufacturing process

1. Selection of base material: the base material of patterned steel plate can be cold-rolled or hot-rolled ordinary carbon structural steel, stainless steel, aluminum alloy and so on.

2. Design pattern: Designers design various patterns, textures or patterns according to the demand.

3. Patterned treatment:

Embossing: Using special embossing equipment, the designed pattern is pressed onto the surface of the steel plate.

Etching: Through chemical corrosion or mechanical etching, the surface material is removed in a specific area to form a pattern.

Laser cutting: Using laser technology to cut the surface of the steel plate to form a precise pattern. 4.

4. Coating: The surface of the steel plate may be treated with anti-corrosion coating, anti-rust coating, etc. to increase its corrosion resistance.

Advantages of checker plate

1. Decorative: Patterned steel plate can be artistic and decorative through various patterns and designs, providing a unique appearance for buildings, furniture and so on.

2. Personalization: It can be personalized according to the need, adapt to different decoration styles and personal taste.

3. Corrosion resistance: If treated with anti-corrosion treatment, the patterned steel plate can have better corrosion resistance and prolong its service life.

4. Strength and abrasion resistance: the base material of patterned steel plate is usually structural steel, with high strength and abrasion resistance, suitable for some scenes with requirements on material performance.

5. Multi-material options: can be applied to a variety of substrates, including ordinary carbon structural steel, stainless steel, aluminum alloys and so on.

6. Multiple production processes: Patterned steel sheets can be produced by embossing, etching, laser cutting and other processes, thus presenting a variety of surface effects.

7. Durability: After anti-corrosion, anti-rust and other treatments, the patterned steel plate can maintain its beauty and service life for a long time in various environments.

Application Scenarios

1. Building decoration: Used for indoor and outdoor wall decoration, ceiling, staircase handrail, etc.

2. Furniture manufacturing: to make desktop, cabinet doors, cabinets and other decorative furniture.

3. automobile interior: applied to the interior decoration of cars, trains and other vehicles.

4. Commercial space decoration: used in stores, restaurants, cafes and other places for wall decoration or counters.

5. artwork production: used to produce some artistic crafts, sculpture and so on.

6. Anti-slip flooring: some pattern designs on the floor can provide anti-slip function, suitable for public places.

7. Shelter boards: Used to make shelter boards to cover or isolate areas.

8. door and window decoration: used for doors, windows, railings and other decorations, to enhance the overall aesthetics.

Post time: Apr-11-2024