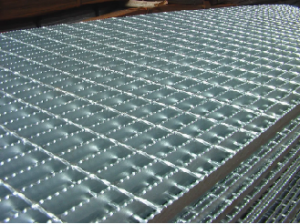

Steel grating is an open steel member with load-bearing flat steel and crossbar orthogonal combination according to a certain spacing, which is fixed by welding or pressure locking; the crossbar is generally made of twisted square steel, round steel or flat steel, and the material is divided into carbon steel and stainless steel. Steel grating is mainly used to make steel structure platform plate, ditch cover plate, steel ladder step plate, building ceiling and so on.

Steel grating is generally made of carbon steel, hot-dip galvanized appearance, can play a role in preventing oxidation. It can also be made of stainless steel. Steel grating has ventilation, lighting, heat dissipation, anti-skid, explosion-proof and other properties.

Pressure welding steel grating

At each intersection of the load-bearing flat steel and the crossbar, the steel grating fixed by pressure resistance welding is called pressure-welded steel grating. The cross bar of press welded steel grating is usually made of twisted square steel.

Press-locked steel grating

At each intersection of load-bearing flat steel and crossbar, the crossbar is pressed into the load-bearing flat steel or pre-slotted load-bearing flat steel by pressure to fix the grating, which is called press-locked grating (also called plug-in grating). The crossbar of press-locked grating is usually made of flat steel.

Characteristics of steel grating

Ventilation, lighting, heat dissipation, explosion-proof, good anti-slip performance: acid and alkali corrosion capacity:

Anti-accumulation of dirt: no accumulation of rain, ice, snow and dust.

Reduce wind resistance: due to good ventilation, small wind resistance in case of high wind, reduce wind damage.

Lightweight structure: use less material, light structure, and easy to hoist.

Durable: hot-dip zinc anti-corrosion treatment before delivery, strong resistance to impact and heavy pressure.

Saving time: the product does not need to be reworked on site, so installation is very fast.

Easy construction: fixing with bolt clamps or welding on the pre-installed support can be done by one person.

Reduced investment: save materials, labor, time, free of cleaning and maintenance.

Material saving: the most material-saving way to bear the same load conditions, accordingly, the material of the support structure can be reduced.

Post time: Aug-20-2024